What is a Certificate of Constancy Performance/COCOP and what is AVCP? ![]()

We operate in an industry full of acronyms and we are sometimes asked, ‘what are COCOP and AVCP?’ COCOP and AVCP are an essential part of UKCA/CE marking, but the terms are not often used or explained. As the majority of Rutland’s door closers are UKCA/CE certified, it’s our job to know about this stuff, so here’s our quick guide to how it all fits together.

What does COCOP stand for?

COCOP stands for ‘Certificate of Constancy of Performance’. In a nutshell, COCOP is the correct name for what the trade commonly, but technically incorrectly, calls the ‘CE certificate’. If a product has a CE marking, it will have a COCOP, and vice versa.If a product has a COCOP, it means that the standards it claims to have met have been achieved through testing systems that have been agreed and harmonised throughout the EU, or designated by the UK. Additionally, it means that the product has been manufactured with these standards in mind.

What is the Declaration of Performance?

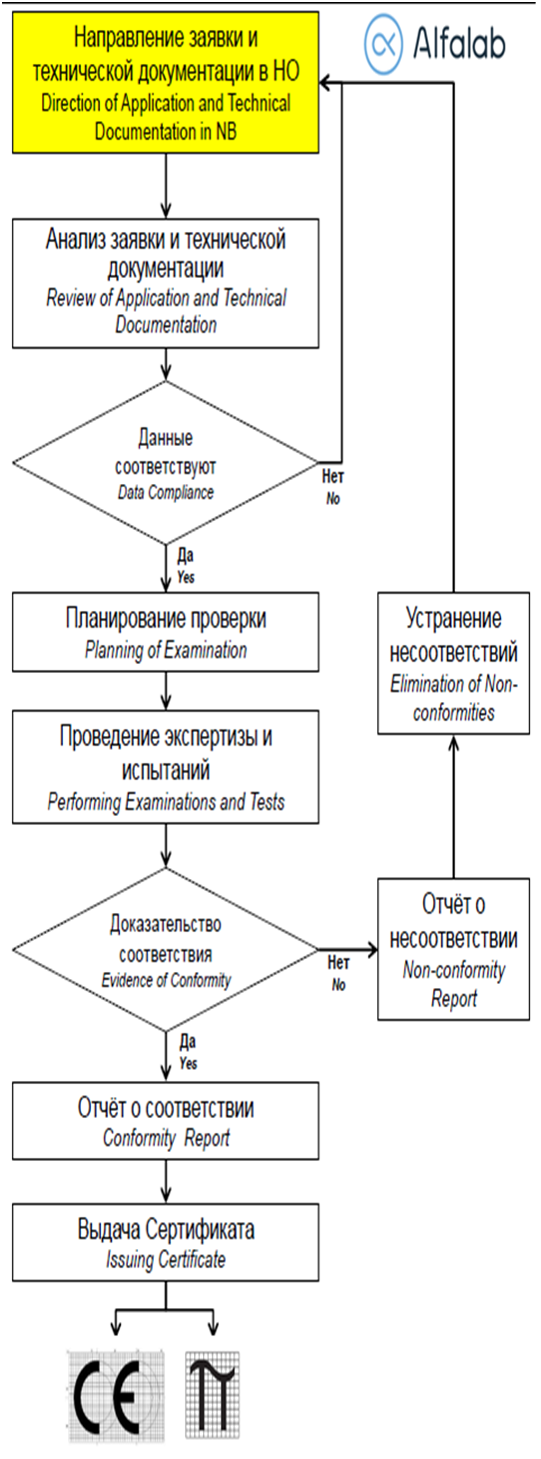

Each construction product with UKCA/CE marking must be accompanied by a Declaration of Performance (DoP). The DoP is the most important document supporting the UKCA/CE marking because it contains the full information about the manufacturer, the product and its performance. Naturally, in order to be able to draw up a Declaration of Performance, manufacturers must have gone through a process which includes phases of documentation, third-party verification and finally certification.

What products include the COCOP certificate?

All kinds of metal doors

All kinds of urban furniture

All types of steel and aluminum guardrails

All types of metal bases for highway lights

All kinds of fences and guards

Countries that accept COCOP certificate:

European Union member states and Norway, Island, Bosnia and Herzegovina, Serbia, Montenegro, Kosovo, Macedonia , Albania, Switzerland, Belarus, Ukraine, Georgia, Moldova, Turkey, Lihtenstein, Andorra, Vatican, San Marino

EN ISO 14122-1:2016

Safety of machinery – Permanent means of access to machinery – Part 1: Choice of fixed means and general requirements of access

EN ISO 14122-2:2016

Safety of machinery – Permanent means of access to machinery – Part 2: Working platforms and walkways

EN ISO 14122-3:2016

Safety of machinery – Permanent means of access to machinery – Part 3: Stairs, stepladders and guardrails

EN ISO 14122-4:2016

Safety of machinery – Permanent means of access to machinery – Part 4: Fixed ladders

EN 1317 Part 1: Terminology and general criteria for test methods

EN 1317 Part 2: Performance classes, impact test acceptance criteria and test methods for safety barriers and vehicle parapets

EN 1317 Part 3: Performance classes, impact test acceptance criteria and test methods for crash cushions

ENV 1317 Part 4: Performance classes, impact test acceptance criteria and test methods for terminals and transitions of safety barriers *

EN 1317 Part 5: Product requirements and evaluation of conformity for vehicle restraint systems

TR 1317 Part 6: Pedestrian parapets

TS 1317 Part 8: Motorcycle road restraint systems which reduce the impact severity of motorcyclist collisions with safety barriers

EN 1090-1: Execution of steel structures and aluminum structures - Part 1: Requirements for conformity assessment of structural components

EN 1090-2: Execution of steel structures and aluminum structures - Part 2: Technical requirements for steel structures

This part defines the technical requirements for the production of steel structures, which must be observed in order to ensure a suitable level of mechanical resistance and stability, as well as usability and durability.

EN 1090-3: Execution of steel structures and aluminum structures - Part 3: Technical requirements for aluminum structures

This part defines the technical requirements for the production of aluminum structures.

EN ISO 1461:2022 Hot dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods

EN ISO 14713-1:2017 Zinc coatings — Guidelines and recommendations for the protection against corrosion of iron and steel in structures